All about Car Crushers

The swan song for almost every new car is a trip to the crusher – a massive machine whose purpose is to compress a car into a flattened slab of metal. Car crushers are an important part of the automotive recycling industry and in this article we’ll learn more about how they work.

What car crushers are

A car crusher is a special kind of press used to compress the metal remains of a junked car. This is generally done after the vehicle has been stripped of all useful parts. The reason that cars are crushed is simple; they take up less space and are easier to transport to a recycling facility.

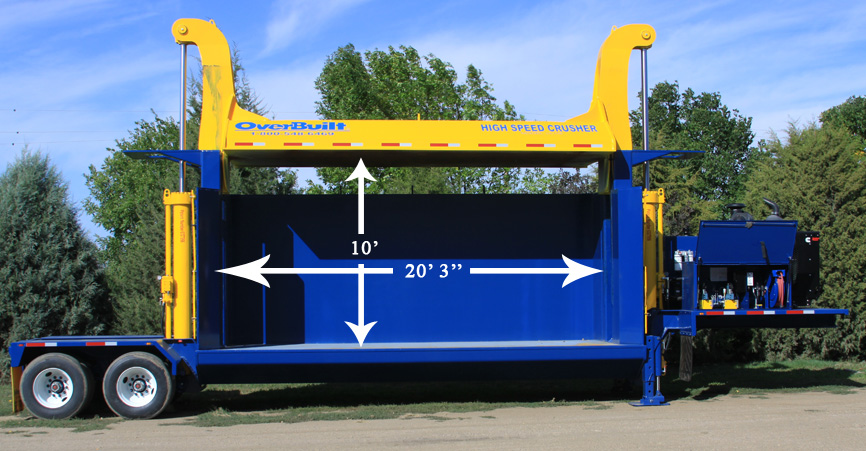

Crushers can be portable or stationary. The older machines tend to be stationary – once they are installed and setup, they stay there. Today, however, most car crushers are portable. They are mounted to a heavy duty truck trailer so they can easily be towed to locations where they are needed. This dramatically cuts costs for scrap yards because instead of buying a stationary machine, they can simply rent a portable crusher when needed.

How they work

Almost all modern car crushers use massive hydraulic pistons to crush vehicles. A large diesel motor powers a pump that pushes hydraulic fluid to drive the pistons. Using principles of force-multiplication, the typical crusher generates 2,000 psi and can impart more than 150 tons of crushing force onto a vehicle.

The different types of crushers

The standard crusher flattens a vehicle into a flat shape. The hydraulic pistons drive a metal crushing plate down vertically reducing a car to a height of just 1-2 feet thick. Adel Chrysler of Adel, IA, a full-service Dodge, Chrysler, Jeep, Ram dealer, says this type of crusher is the most common one used.

In a “bale” crusher, another set of pistons pushes another crushing plate from the sides after it is flattened vertically. This forms the junk car into a rectangular shape that looks like a large metal “hay bale.”

The last type of crusher is called a hammer crusher. These aren’t as much crushers as they are shredders. They use hammer-like objects connected to spinning wheels that simply smash the vehicle into smaller pieces.

Prepping a car

Before crushing a vehicle is stripped of all parts that can be resold. For example, a car may come in because its rusty but the engine and transmission operate fine. Salvage crews will pull these components out of the vehicle along with just about any other part that can be resold. Today, the reselling of car parts is a huge business with the internet connecting buyers and sellers worldwide.

Before a car is stripped, all the hazardous materials are removed. The battery is removed, the Freon in the AC system is recovered by a special machine and the gas tank is removed and drained. If the engine is left in the car, the antifreeze and oil are drained.

The recycling ecosystem

The sale of crushed cars is only a small piece of the auto recycling . About 65 percent of a junked car is made from steel, the rest is made up of materials such as glass, rubber and plastic. The price for scrap steel and iron is rather volatile but often lands from $150 to $250 per ton. The expanding economies in Asia have led to greater demand for scrap steel. Approximately 14 million tons of steel is recycled every year in North America.

Photo credit : Overbuilt.com