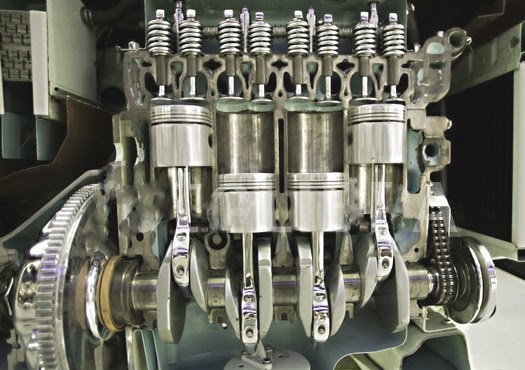

The Internal Combustion Engine Gets Modern

Yes, its old and it pollutes but the hydrocarbon-fueled, reciprocating-piston internal-combustion engine simply works. There have been competitors over the years, such as steam and electric engines, but they weren’t true competitors after the turn of the 20th century. The internal combustion engine won the race and has maintained its leadership position by virtue of its practicality and low cost. Almost 100 years later, it’s still with us. Of course, that doesn’t mean that it can’t be improved. Let’s take a look at four improvements being worked on as we speak.

48-Volt Electrical Systems

One of the key technologies that will help internal combustion engines efficiency is the 48-volt electrical system. Here’s why: most of today’s engines use a belt to drive alternators, water pumps, power steering pumps, and AC compressors. Problem is they generally run continuously. Stepping up to the power output enabled by 48-volt generators will allow these accessory drives to go electric. This will be a big engineering project but it will reduce the parasitic loads on engines and potentially boost fuel mileage by about 10 percent. According to Susquehanna Chrysler of Wrightsville, a local Chrysler, Dodge, Jeep, Ram, Fiat dealer in Wrightsville, PA, Sergio Marchionne, the CEO of FCA, the company is developing 48 volt systems as we speak.

Cylinder Deactivation

For the 1981 model year, Cadillac experimented with a new technology called Cylinder Deactivation. This was a system that could switch off two or four cylinders depending on the load and thus save gas. It was a good idea but a disastrous execution. Today, because of advanced electronics and sensors, the technique is works well. According to GM, cylinder deactivation cut fuel consumption by as much as 15 percent.

Camshaft-Less Engines

An internal combustion engine pumps air and fuel into the engine cylinders, burns it, and then purges the burnt gases. This is accomplished with camshafts that open and close the cylinder valves. It is a far from perfect method, though; the optimal timing when the intake and exhaust valves open and close depends on engine speed and load. Unfortunately, solid camshafts can’t change their timing as loads change so the timing is a compromise design. Ideally, each valve would be managed by its own actuator, perfectly timed for what is happening with the cylinders and crankshaft position. The shift toward 48-volt electrical systems will allow engineers to design cam-less engines which will be far more efficient than the old cam designs.

Electric Superchargers

The turbocharger is another classic piece of engine technology that has received a new lease on life in recent years. The problem is “turbo-lag.” This is the delay in boost that occurs with a turbo-equipped engine because it takes a few seconds for a turbocharger to spin up to speed. A solution is to drive the turbine with an electric motor instead of exhaust gases. The response of an electrically-driven compressor can be almost instantaneous and can be modulated according to the engine conditions. Audi’s SQ7 TDI is the first production vehicle to use an electric supercharger, and we expect more to follow.

Variable Compression Pistons

When maximum torque is needed from an engine, a higher compression ratio helps. Unfortunately, when torque isn’t needed, high compression reduces efficiency. This was just the status quo years ago. Today we have modern electronic systems that can change the compression ratio of an engine’s cylinders as it runs by varying the valve timing. Engineers say that this can improve efficiency some 12 percent.